The Making of a Dabbawalla Bag

Here at Dabbawalla Bags, we get calls all the time asking us about where we manufacture our bags, the type of facility and working conditions and how we know they are being paid fairly. We LOVE these calls because we are quite passionate about how our bags are sewn and the type of organization we want to work with. Over the course of our 10 years in business, we have literally visited dozens and dozens of factories around the world, and we are so proud of OUR factory and its commitment to families.

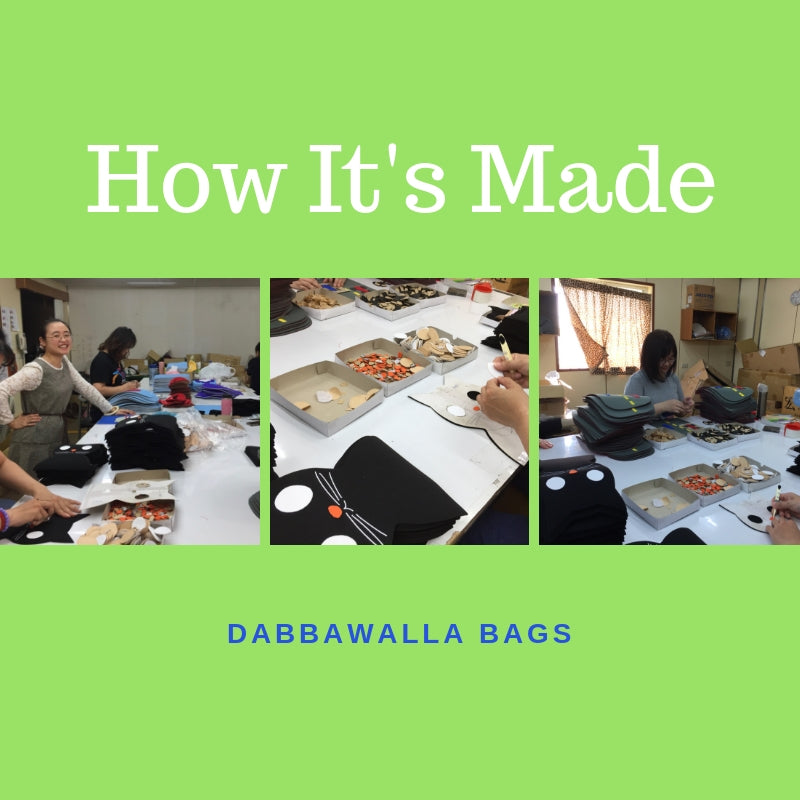

While our bags are designed in Seattle, they are sewn in southern Taiwan at a small, woman-owned sewing facility. They are like a second family to us and our frequent visits feel like we are coming home. Our factory is in a part of the world were women don't have as many opportunities as we do here in the US, and many are the primary breadwinners in their family or have difficult personal situations. Our success allows these women a stable income, and a working environment that is safe, comfortable and productive. We are so fortunate to be part of this facility where individual seamstresses individually craft each bag with LOVE.

We've partnered with them since the beginning of Dabbawalla Bags and have gotten to know them and their families. Our regular visits to the facility have allowed us to connect with them on an individual level.

Each of our bags are individually sewn, and hand-crafted by these talented seamstresses. Because our bags are made one at a time, it allows subtle differences that add to their unique charm and character.

It is important to us, here at Dabbawalla Bags, that our workers are as happy as our customers. Which is why the facility we partner with is dedicated to responsible labor practices and workers receive benefits and fair-trade wages. And for the health of our children, workers and the environment, all of our bags are made from a 100% toxic free and eco-friendly material called TPE.

For a closer look at how are bags are made, here is a quick video: